Basic Info.

Model NO.

Glass Optical Fiber

Core

Single Core

Certification

RoHS, CE, ISO9001, CCC

Brand

OEM

Sheath Material

Optical Fiber

MOQ

100km

Roduction Capacity

10 Million Cores/Year

Color

Bare

Transport Package

Plastic Drum

Specification

48.8 km/roll

Trademark

FIBCONET

Origin

Ningbo, China

HS Code

9001100001

Production Capacity

10 Million Cores/Year

Product Description

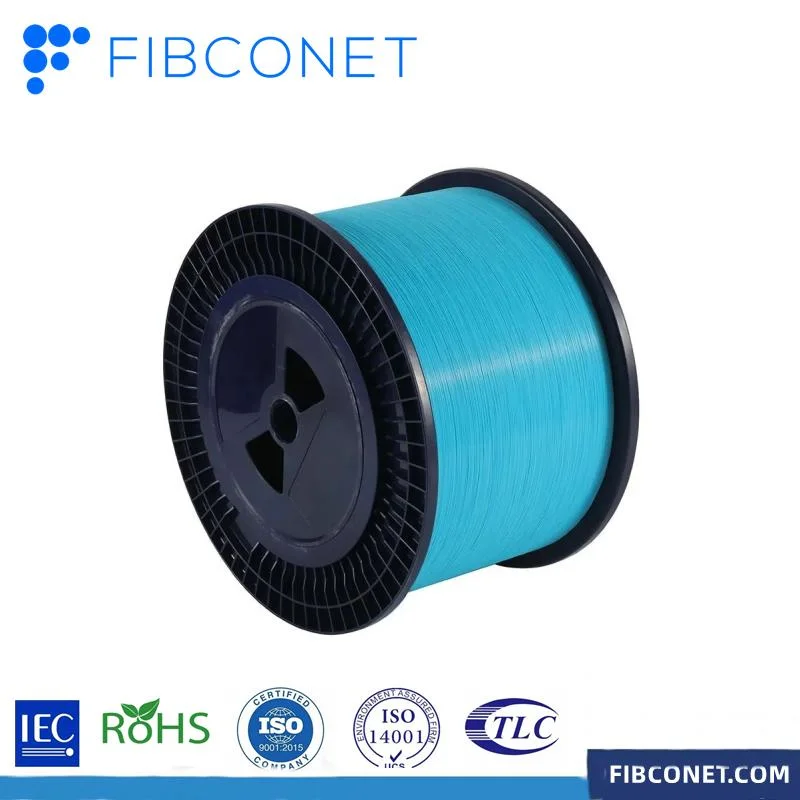

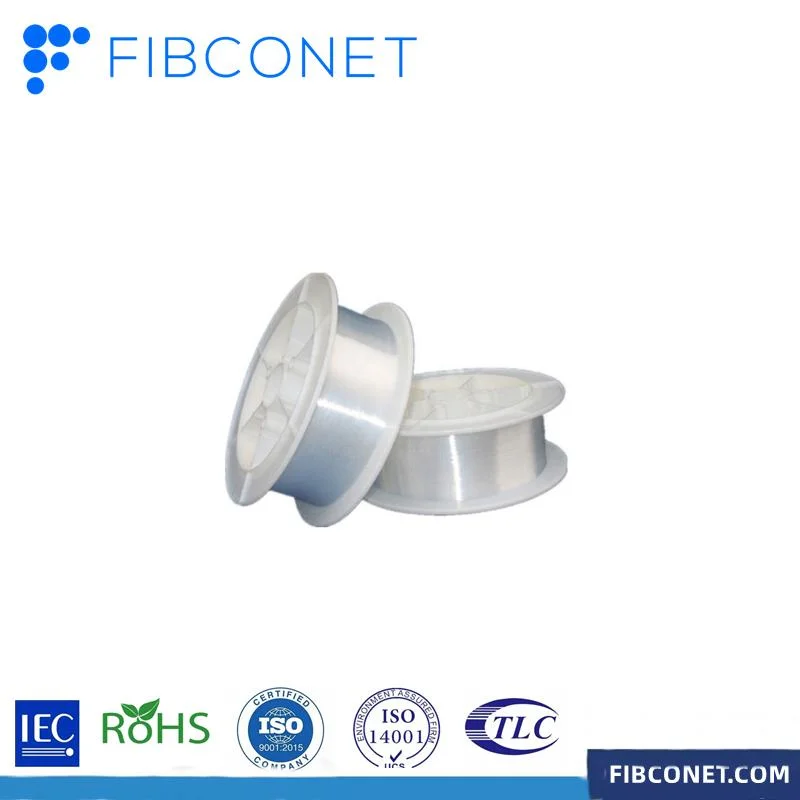

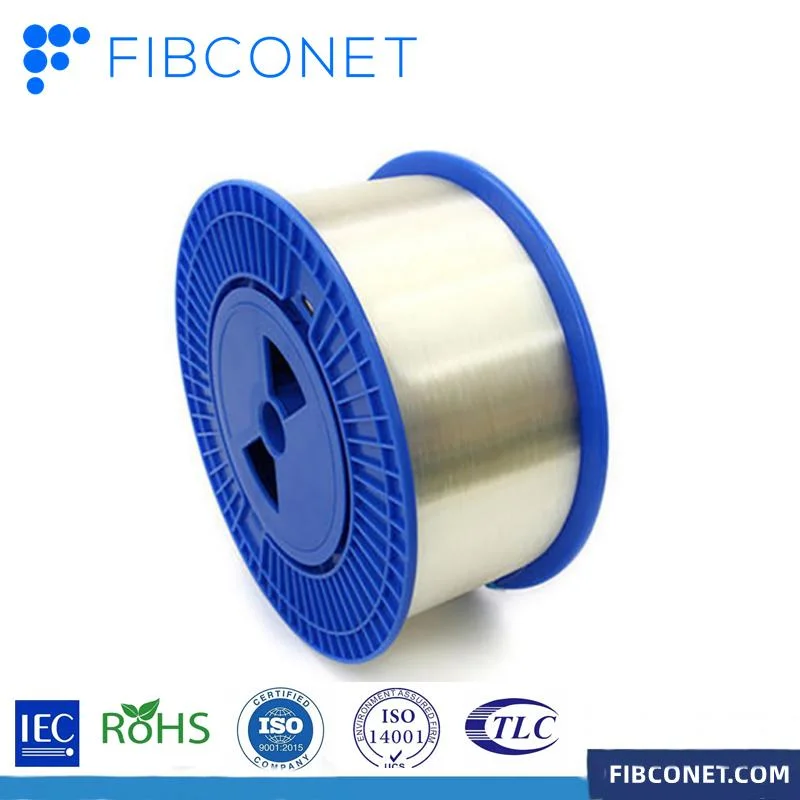

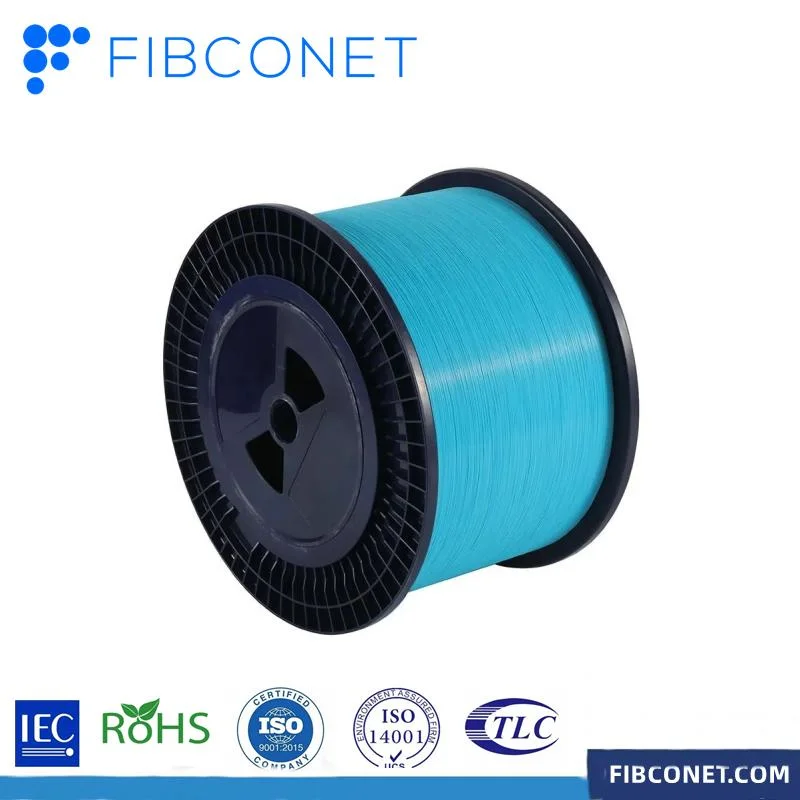

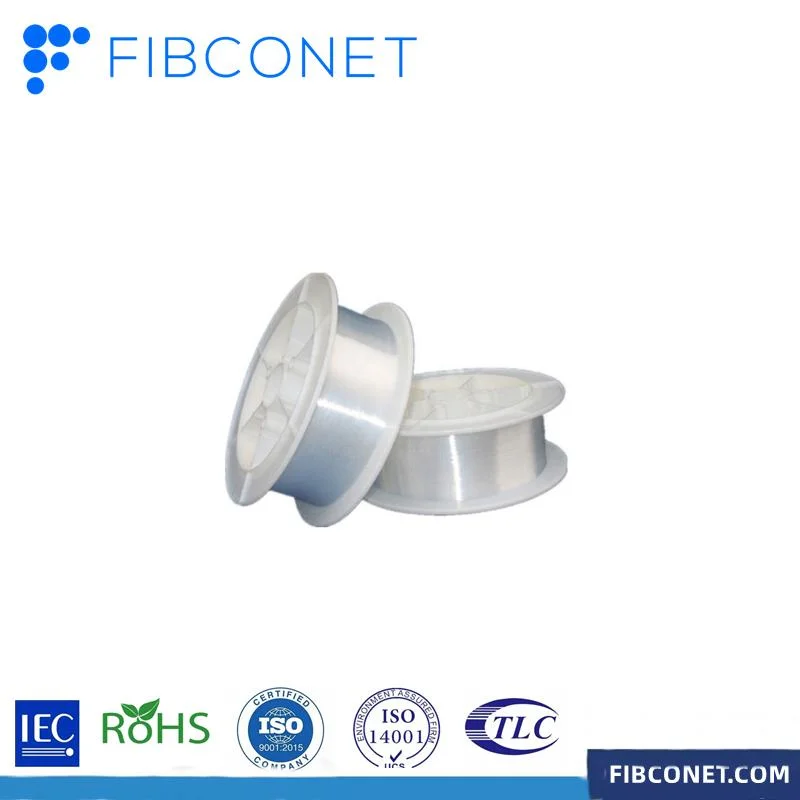

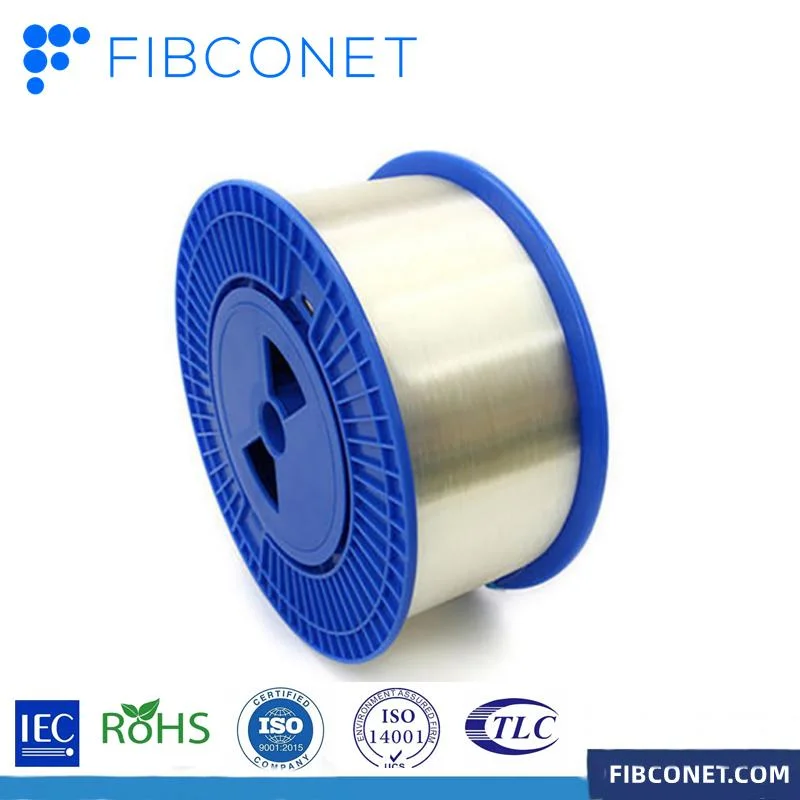

Hot sale G654D/G657A1 2km/5km/10KM Single-Mode Glass Optical Fiber

Glass optical fibers are constructed of tiny strands of glass that are bundled together inside an application-specific sheathing like stainless steel for durability and high temperatures. They are attached to certain photoelectric sensors and guide light from the sensing head to the target. Glass optical fibers have an impressive temperature range, as low as -40°F and up to +900°F. The main applications for glass fiber are communication, sensor, and measurement system. Some types of glass optical fiber cables can also be used in harsh environments such as corrosive and wet environments.

Specification

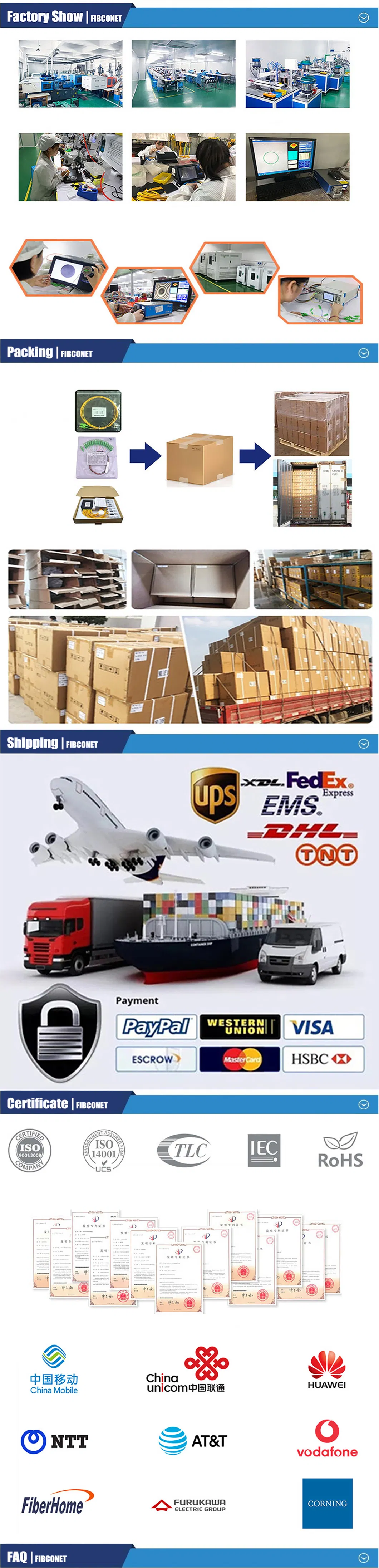

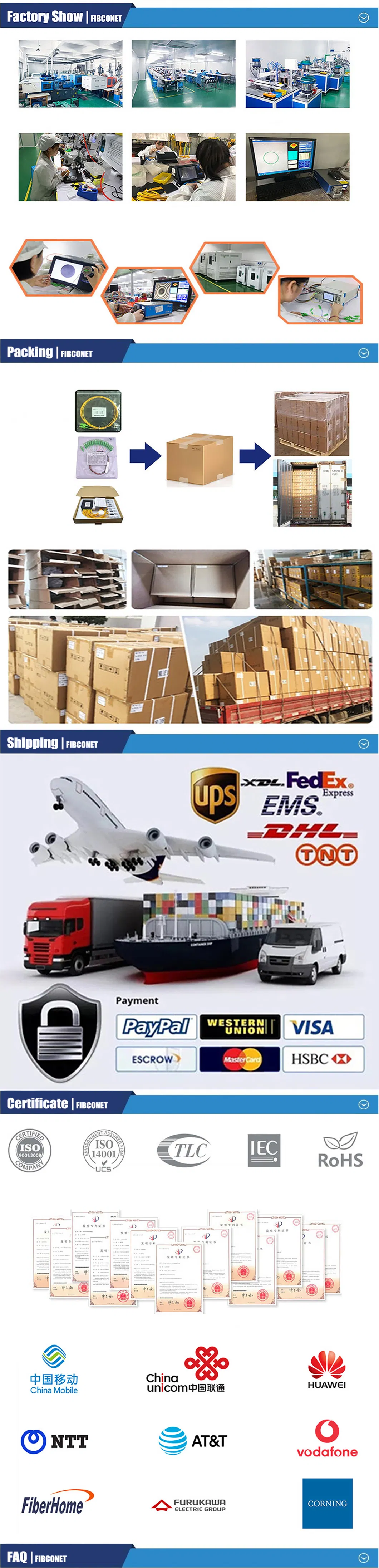

Starting with the Copper age in 1992, FIBCONET has gone through nearly 18 years in the fiber optic communication area.

Starting with the Copper age in 1992, FIBCONET has gone through nearly 18 years in the fiber optic communication area.

Now FIBCONET has 3 manufacturing centers, Ningbo, Guizhou, and Northeast China, covering more than 10,000 sqm,

owning 800 well-trained staff and engineers, reaching the production capacity of PLC Splitter in 300,000 pcs and fiber optical

connectors in 10 million pcs per month. As the national high-tech enterprise, FIBCONET also strives for more efforts in innovation.

50 patents and 15 invention patents have been attained.

FIBCONET focus on the fiber optical components, such as PLC splitter,

patch cord, adapter, connectors, etc. Especially for the PLC splitter, can work in an extremely cold environment, even in the -50

centigrade degree, like in Russia, FIBCONET's PLC can still help transmit the optical signal very well, And if you hope to get the

0.1 dB for insert loss on your connectors, which is hard for the regular production, FIBCONET also can reach you.

FIBCONET supplies goods all over the world through trading companies and agents, like Corning in the USA, Vodafone in Europe,

Furukawa in Japan., etc. ISO9001, Rohs, and TLC certificates have already been approved by the market and our customers.

With the new corporate vision: To be the top supplier for the fiber optical components, "Keep connecting" is our Motto, not only means

that we produce the connectors and connect the fiber optic equipment, but also connect with the new technology, connect with every

FIBCONET person connects with our customers worldwide.

Q: The History of our factory?

A: In 2000, Fibconet entered the communications industry and began to make adapters. It accumulated funds to invest in jumper production in 2006 and increased the optical splitter workshop in 2009. Fibconet won the national high-tech industry in 2013, sold over 15 million US dollars in 2015, and began to explore foreign markets.

Q: The location of our factory?

A: Our factory is located in Ningbo, Zhejiang, and our new factory has also been put into production, located in the Northeast (Jilin Province).

Q: Occupied area for our factory?

A: The construction area of our factory is about 23,000 square meters, including 8000 square meters in Fenghua Plant and 15,000 square meters in Northeast China.

Q: Production capacity for the Patch cord?

A: 5,000,000 pcs per month.

Q: What's your best price for your passive fiber optic product?

A: Based on the quality of our products and the quantity of your estimated. We would quote the great best matching price all the time.

Q: Do you offer a guarantee for the products?

A: Yes, we offer a 1-2 years warranty on our formal products.

Q: What action will you take if there are some product problems?

A: If there are defective ones in the batch of products, we will offer spare ones.

Glass optical fibers are constructed of tiny strands of glass that are bundled together inside an application-specific sheathing like stainless steel for durability and high temperatures. They are attached to certain photoelectric sensors and guide light from the sensing head to the target. Glass optical fibers have an impressive temperature range, as low as -40°F and up to +900°F. The main applications for glass fiber are communication, sensor, and measurement system. Some types of glass optical fiber cables can also be used in harsh environments such as corrosive and wet environments.

Feature

- Minimum bend radius 7.5mm, superior anti-bending property;

- Fully compatible with G.652 single-mode fiber. Full band (1260~1626nm) transmission;

- Low PMD for high bit-rate and long distance transmission. Extremely low micro-bending attenuation, applicable for all optical cable types including ribbons;

- High anti-fatigue parameter ensures service life under small bending radius.

Application: All cable constructions, 1260~1626nm full band transmission, FTTH high speed optical routing, optical cable in small bend radius, small-size optical fiber cable and device, L-band.

Specification

| TESTING REPORT FOR B1.3(G652D) | |||

| Optics Specifications | Result | ||

| Attenuation(dB/km) | @1310nm | ≤0.34db/km | Comply |

| @1383nm (after hydrogen aging) | ≤0.32db/km | Comply | |

| @1550nm | ≤0.22db/km | Comply | |

| @1625nm | ≤0.24db/km | Comply | |

| Dispersion | @1285nm~1340nm | -3.0~3.0ps/(nm*km) | Comply |

| | @1550nm | ≤18ps/(nm*km) | Comply |

| | @1625nm | ≤22ps/(nm*km) | Comply |

| Zero-Dispersion wavelength | 1300~1324nm | | |

| Zero-Dispersion slope | ≤0.092ps/(nm2*km) | | |

| Mode field diameter @ 1310nm | 9.2±0.4μm | | |

| Mode field diameter @ 1550nm | 10.4±0.8μm | | |

| PMD | Max. value for fiber on the reel | 0.2ps/km 1/2 | Comply |

| Max. Designed value for link | 0.08ps/km 1/2 | Comply | |

| Cable cutoff wavelength,λ cc | ≤1260nm | Comply | |

| Effective group index(Neff)@1310nm | 1.4675 | Comply | |

| Effective group index(Neff)@1550nm | 1.4680 | Comply | |

| Macro-bend loss(Φ60mm,100 turns)@1550nm | ≤0.05db | Comply | |

| Back scatter characteristic(@1310nm&1550nm) | Result | ||

| Point discontinuity | ≤0.05db | Comply | |

| Attenuation uniformity | ≤0.05db/km | Comply | |

| Attenuation coefficient difference for bi-directional measurement | ≤0.05db/km | Comply | |

| Geometrical characteristics | Result | ||

| Cladding diameter | 125±1μm | Comply | |

| Cladding non-circularity | ≤1% | Comply | |

| Core/cladding concentricity error | ≤0.4μm | Comply | |

| Fiber diameter with coating(uncolored) | 245±5μm | Comply | |

| Cladding/coating concentricity error | ≤12.0μm | Comply | |

| Curl | ≥4m | Comply | |

| Mechanical characteristic | Result | ||

| Proof test | | 0.69GPa | Comply |

| Proof test | | 1.4N | Comply |

| Dynamic stress corrosion susceptibility parameter(typical value) | | ≥20 | Comply |

| Environmental characteristics(@1310nm&1550nm) | Result | ||

| Temperature induced attenuation(-60~+85ºC) | | ≤0.5dB/km | Comply |

| Dry heat induced attenuation(85±2ºC,30days) | | ≤0.5dB/km | Comply |

| Water immersion induced attenuation(23±2ºC,30days) | | ≤0.5dB/km | Comply |

| Damp heat induced attenuation(85±2ºC,RH85%,30days) | | ≤0.5dB/km | Comply |

Starting with the Copper age in 1992, FIBCONET has gone through nearly 18 years in the fiber optic communication area.

Starting with the Copper age in 1992, FIBCONET has gone through nearly 18 years in the fiber optic communication area. Now FIBCONET has 3 manufacturing centers, Ningbo, Guizhou, and Northeast China, covering more than 10,000 sqm,

owning 800 well-trained staff and engineers, reaching the production capacity of PLC Splitter in 300,000 pcs and fiber optical

connectors in 10 million pcs per month. As the national high-tech enterprise, FIBCONET also strives for more efforts in innovation.

50 patents and 15 invention patents have been attained.

FIBCONET focus on the fiber optical components, such as PLC splitter,

patch cord, adapter, connectors, etc. Especially for the PLC splitter, can work in an extremely cold environment, even in the -50

centigrade degree, like in Russia, FIBCONET's PLC can still help transmit the optical signal very well, And if you hope to get the

0.1 dB for insert loss on your connectors, which is hard for the regular production, FIBCONET also can reach you.

FIBCONET supplies goods all over the world through trading companies and agents, like Corning in the USA, Vodafone in Europe,

Furukawa in Japan., etc. ISO9001, Rohs, and TLC certificates have already been approved by the market and our customers.

With the new corporate vision: To be the top supplier for the fiber optical components, "Keep connecting" is our Motto, not only means

that we produce the connectors and connect the fiber optic equipment, but also connect with the new technology, connect with every

FIBCONET person connects with our customers worldwide.

Q: The History of our factory?

A: In 2000, Fibconet entered the communications industry and began to make adapters. It accumulated funds to invest in jumper production in 2006 and increased the optical splitter workshop in 2009. Fibconet won the national high-tech industry in 2013, sold over 15 million US dollars in 2015, and began to explore foreign markets.

Q: The location of our factory?

A: Our factory is located in Ningbo, Zhejiang, and our new factory has also been put into production, located in the Northeast (Jilin Province).

Q: Occupied area for our factory?

A: The construction area of our factory is about 23,000 square meters, including 8000 square meters in Fenghua Plant and 15,000 square meters in Northeast China.

Q: Production capacity for the Patch cord?

A: 5,000,000 pcs per month.

Q: What's your best price for your passive fiber optic product?

A: Based on the quality of our products and the quantity of your estimated. We would quote the great best matching price all the time.

Q: Do you offer a guarantee for the products?

A: Yes, we offer a 1-2 years warranty on our formal products.

Q: What action will you take if there are some product problems?

A: If there are defective ones in the batch of products, we will offer spare ones.