Basic Info.

Model NO.

GYTA

Material Shape

Round Wire

Allowed Lateral Pressure

>1000(N/100mm)

Allowed Tensile Strength

>10000N

Core

Multicore

Certification

RoHS, CE, ISO9001, VDE, CCC

Brand

Fcj Opto Tech

Sheath Material

PE

Central Strength Member

Steel Wire

Armoured

Al Tape

Fiber Options

Itu G652D ,G657A,Om1,Om2,Om3,Om4

Installation Tensile

1500n

Place of Origin

Zhejiang

Transport Package

Wooden Drum and Carton

Specification

GYTA

Trademark

FCJ OPTO TECH

Origin

China

HS Code

854470000

Production Capacity

8000km/Momth

Packaging & Delivery

Package Size

100.00cm * 20.00cm * 10.00cm

Package Gross Weight

10.000kg

Product Description

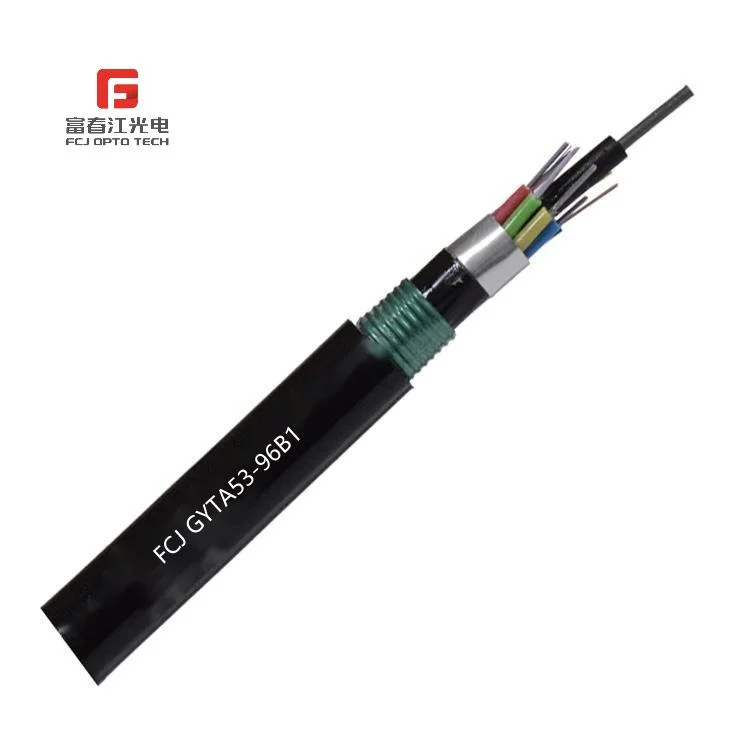

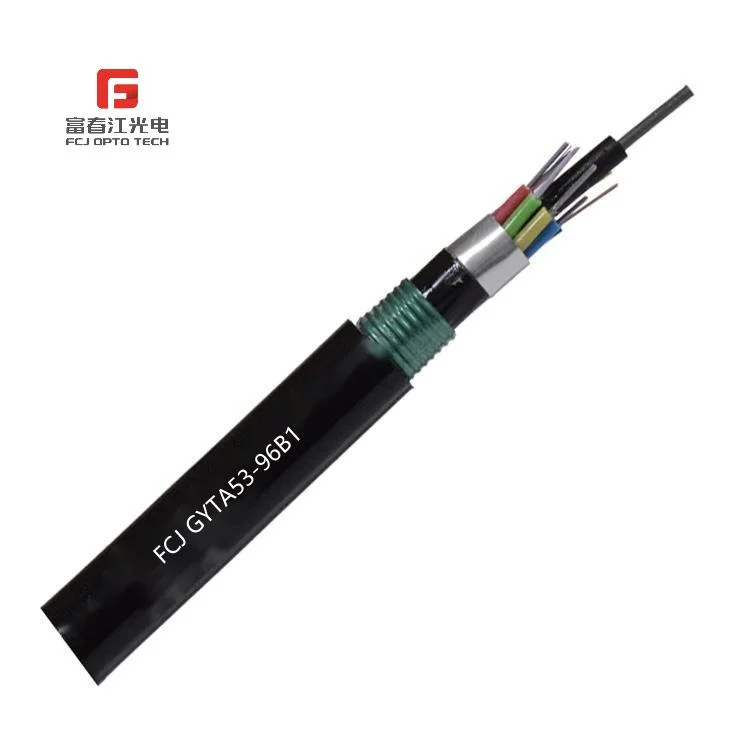

FCJ Water-Resistant GYTA Armoured Single Mode Outdoor Underground Fiber Optic Cable

Description

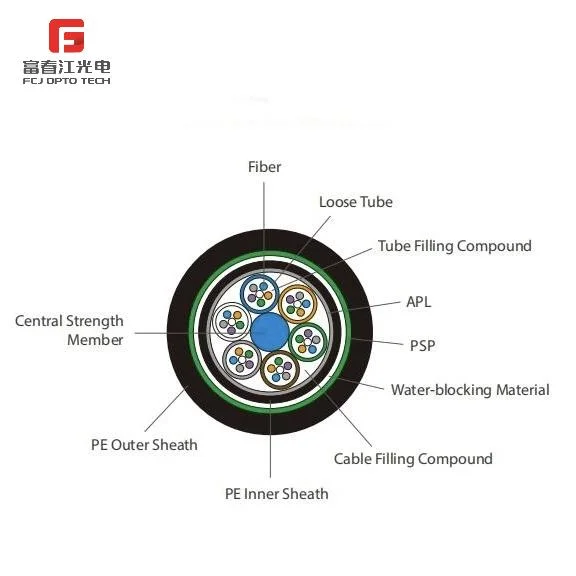

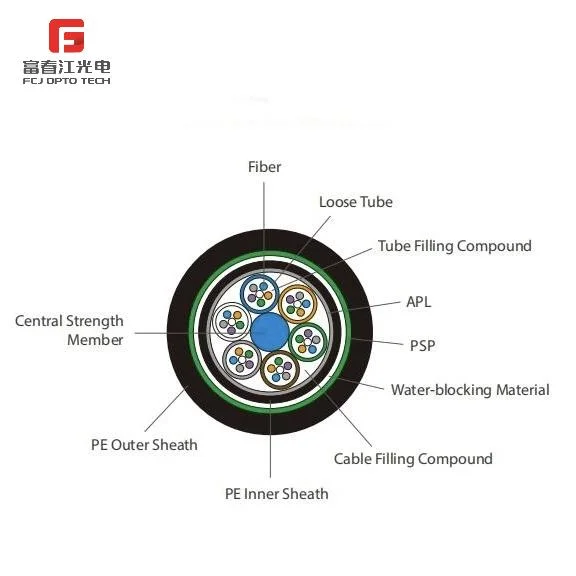

The fibers, 250μm, are positioned in a loose tube made of a high modulus plastic. The tubes are filled with a water-resistant filling compound. A steel wire, sometimes sheathed with polyethylene (PE) for cable with high fiber count, locates in the center of core as a metallic strength member. Tubes (and fillers) are stranded around the strength member into a compact and circular cable core. The cable core is filled with the filling compound to protect it from water ingress, over which a thin PE inner sheath is applied. After the PSP is longitudinally applied over the inner sheath, the cable is completed with a PE outer sheath.

Characteristics

· Good mechanical and temperature performance

· High strength looes tube that is hydrolysis resistant

· Special tube filling compound ensure a critical protection of fiber

· Crush resistance and flexibilit

· The following measures are taken to ensure the cable watertight:

- Steel wire used as the central strength member

- Loose tube filling compound

- 100% cable core filling

- PSP enhancing moisture-proof

- Water-blocking material

Standards

GYTA53 cable complies with Standard YD/T 901-2001as well as IEC 60794-1.

Optical Characteristics

Technical Parameters

Storage/Operating Temperature : -40ºC to + 70ºC

Description

The fibers, 250μm, are positioned in a loose tube made of a high modulus plastic. The tubes are filled with a water-resistant filling compound. A steel wire, sometimes sheathed with polyethylene (PE) for cable with high fiber count, locates in the center of core as a metallic strength member. Tubes (and fillers) are stranded around the strength member into a compact and circular cable core. The cable core is filled with the filling compound to protect it from water ingress, over which a thin PE inner sheath is applied. After the PSP is longitudinally applied over the inner sheath, the cable is completed with a PE outer sheath.

Characteristics

· Good mechanical and temperature performance

· High strength looes tube that is hydrolysis resistant

· Special tube filling compound ensure a critical protection of fiber

· Crush resistance and flexibilit

· The following measures are taken to ensure the cable watertight:

- Steel wire used as the central strength member

- Loose tube filling compound

- 100% cable core filling

- PSP enhancing moisture-proof

- Water-blocking material

Standards

GYTA53 cable complies with Standard YD/T 901-2001as well as IEC 60794-1.

Optical Characteristics

| G.652 | G.655 | 50/125μm | 62.5/125μm | ||

| Attenuation (+20ºC) | @850nm | ≤3.0 dB/km | ≤3.0 dB/km | ||

| @1300nm | ≤1.0 dB/km | ≤1.0 dB/km | |||

| @1310nm | ≤0.36 dB/km | ≤0.40 dB/km | |||

| @1550nm | ≤0.22 dB/km | ≤0.23 dB/km | |||

| Bandwidth (Class A) | @850nm | ≥500 MHz·km | ≥200 MHz·km | ||

| @1300nm | ≥1000 MHz·km | ≥600 MHz·km | |||

| Numerical Aperture | 0.200±0.015NA | 0.275±0.015NA | |||

| Cable Cut-off Wavelength | ≤1260nm | ≤1480nm | |||

Technical Parameters

Storage/Operating Temperature : -40ºC to + 70ºC