Basic Info.

Product Description

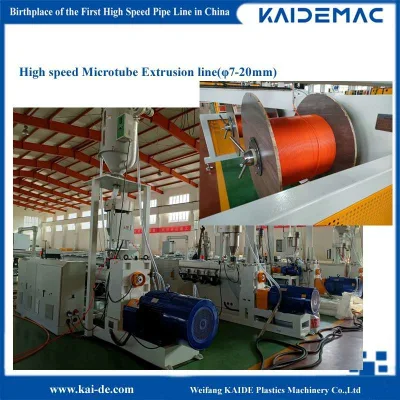

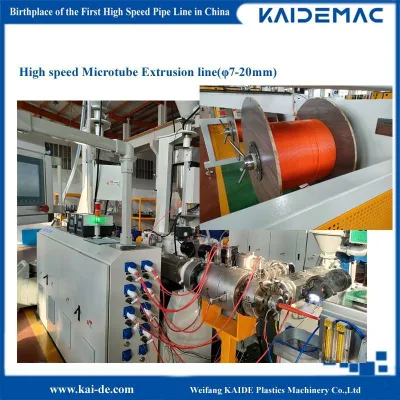

High Speed HDPE Silicon Micro-duct Production Line

This Microduct Production line is used to produce HDPE Silicone Core Micro Duct Pipe, with diameter 5mm-20mm. The Microduct Extrusion Machine equipped with high efficient extruder machine, Precision Graviemter Control System, Composite Professional Multilayer Die Head Moulds, Vacuum System, Cooling System, Stable Haul-off Machine, Servo Traverse Coiler machine.

1. Production Line Model

| Model | Screw Diameter (mm) | Line Speed (m/min) | Power (Kw) | Overall Size (m) |

| KDGX-75 | 75mm | 60m/min | 178KW | 50mx2.5mx3m |

| KDGX-60 | 60mm | 40m/min | 134KW | 40mx2mx3m |

| KDGX-65 | 65mm | 15m/min | 95KW | 31mx2mx3m |

2. High Effient Extruer equipped for this Microduct Production Line

| 1 | Speicall Designed L/D Screw for HDPE Raw Materials |

| 2 | This Exstruder with high capacity, low engery consumption cost |

| 3 | China Famous Brand Reducer Gear box |

| 4 | Temperature Control System by Siemens PLC computer |

3. Double Layers Co-Extrusion Die Head Moulds

- Die Head Materials: 40Cr,

- Independently designed two layers composite die head structure

- Diameter range: 5mm/3.5mm, 7mm/4mm, 12mm/8mm,14mm/10mm,16mm/12mm,18mm/14mm

- Inner Silicon layers 0.2mm

4. High Precision Vacuum Tank

This Microduct Tube production line adopts high precision vacuum tank, which ensures the soonest cooling and pipe forming, when the microduct coms from the die head; Independent patented calibrators was equipped accordingly for this high speed production line.

- Raw materials of Vacuum Tank: National Standard 304#

- With Forward-Backward Guide Rail;

- Water flower Stablizer equipped

5. High Speed and Stable Haul-off Machine Equipped

This Microduct making machine adopts the kaide specially designed haul-off machinery, with servo motor driven, max.haul-off speed 100m/min,Synchronous running with the main extruder.

6. Specially Designed Coiler Machine

This Microduct tube machine with standard equipped winding machine , which has the intelligent functionos, such as automatic pipe traversing, tension control of winding speed, etc. There is no need for any manual intervension to ensure the winding effect during the whole process.

7. Referenced Manufactured Pipe Specification

The main materials is HDPE,composite with silica gel solid lubricant inside the pipe.

| No. | Diameter | Thickness 1 | Thickness 2 |

| 1 | 5mm | 0.75mm | 1.25,mm |

| 2 | 7mm | 0.75mm | 1.5mm |

| 3 | 10mm | 1mm | 2mm |

| 4 | 12mm | 1mm | 2mm |

| 5 | 14mm | 1mm | 2mm |

| 6 | 16mm | 1mm | 2mm |

| 7 | 18mm | 1mm | 2mm |

8.Company View